Construction

Construction

ACCIONA plans to increase its competitive advantage using nano-structured bio-based composites materials as alternatives to conventional materials, like Steel and concrete, in Civil Infrastructure applications, for example construction of bridges. Usage of bio-based materials will help ACCIONA lower its construction cost owing to faster production due to their low curing time, reduce transportation and installation time, thanks to their light weight, and reduce maintenance cost owing to their high corrosión resistance. To achieve this, isocyanate free TPU biopolymers reinforced with NL, biochar and NFC will be used for the construction of a footbridge module (2m x 0.45m x 0.65m) with 3D printing technology. The final product is expected to have high UV and fire resistance >80ºC, anti-fouling & easy-cleaning capability

ΒΙΟΜASS

BIOMASS FRACTIONATION

& PRE-TREATMENT

INTERMEDIATE MATERIALS

PL10 - PRODUCTION OF NANOFIBRILLATED CELLULOSE NFCS

PL8 -BIOMASS CARBONIZATION

FINAL PRODUCTS & FORMULATION

PL9 PRODUCTION OF ISOCYANATE FREE TPU VIA REACTIVE EXTRUSION

PL15 - ADDITIVE MANUFACTURING

Footbridge module with improved UV and fire resistance and thermal conductivity

Demonstrating Sustainable, High-Performance Construction Materials via Additive Manufacturing of Biobased Nanocomposites -BIOMAC Test Case #4

BIOMAC, as an open ecosystem, focuses on the creation and validation of new supply and value chains where technologies that are being scaled up and validated to TRL 7, accelerating their exploitation potential. The BIOMAC OITB has been built to address 5 Test Cases (interTeCs) for the validation selected based on their complexity in order to involve different pilot lines as well as the supporting services, and thus provide holistic feedback for the operation of the OITB as a whole.

This TeC “Construction” is led by ACCIONA and focused on the development and production of a footbridge made with biobased nano-composites biopolymers

1. Materials and Formulation

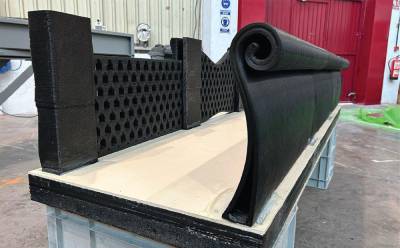

Figure 1: Scale model of the footbridge

|

This Test Case 4 focuses on validating the use of biobased nanocomposite materials in the construction sector, specifically through the development of modular footbridge components.

The matrix material selected for the demonstrator was PLA (Polylactic Acid), a commercially available, biobased thermoplastic (Luminy LX175, NatureWorks). PLA was chosen for its compatibility with Fused Granulate Fabrication (FGF) printing, and its superior stiffness and thermal-mechanical performance relative to other bioplastics evaluated in the project. These properties made it particularly suitable for construction scale applications and large-format additive manufacturing processes.

To enhance the performance of the base polymer, three biobased fillers were incorporated into the formulation. Biochar, produced from Miscanthus biomass via pyrolysis by the University of Edinburgh, was included for its thermal and fireresistant properties. Lignin, extracted from pretreated biomass by BBEPP, added structural and thermal benefits. Nanofibrillated Cellulose, produced by LIST through ultrafine grinding, contributed to mechanical reinforcement. These fillers were compounded with PLA using twin-screw extrusion at LIST, resulting in a printable nanocomposite with improved mechanical strength, thermal stability, UV/fire resistance, and environmental sustainability.

The final formulation used for the demonstrator consisted of 79.21% PLA, 9.9% biochar, 9.9% lignin, and 1% nanocellulose.

2. Manufacturing and Assembly

The demonstrator, a modular footbridge at 1:7 scale, was manufactured using robotic 3D printing via FGF-based pellet extrusion, provided by AIMEN’s pilot line. The printed structure was designed as a modular unit measuring 2000 × 600 × 75 mm, suitable for easy transport, customization, and structural integrity testing.

The final structure featured a 3D-printed biopolymer honeycomb core, which provided compressive and shear resistance, sandwiched between two fiberglass-reinforced skins fabricated through epoxy resin infusion. Additional structural panels and railings were attached to demonstrate design versatility and the adaptability of additive manufacturing for aesthetic and functional modifications.

Post-processing operations, including cutting, sanding, and grinding, were carried out to ensure proper fit and finish of the modules and to correct any imperfections from the printing process. Final assembly involved bonding the fiberglass laminates to the base module and attaching columns and railings using epoxy adhesives.

3. Final product and performance highlights

The demonstrator met or exceeded key mechanical benchmarks, with a flexural strength of at least 100 MPa, a flexural modulus of 8 GPa or higher, and a bearing strength exceeding 15 MPa, in accordance with ASTM D790 and ASTM E238. In terms of thermal and fire resistance, the structure demonstrated a glass transition temperature (Tg) of 80 °C or higher, and achieved Reaction to Fire Class B as per ASTM D648 and ISO 75 standards.

This test case successfully demonstrated the technical and functional feasibility of using sustainable, printable nanocomposites in the construction of structural-scale components. This achievement highlights the potential of biobased materials to replace fossil-based construction materials, offering advantages such as reduced carbon footprint, improved cost-efficiency, and alignment with emerging EU sustainability and circular economy policies. By using commercially available PLA and pilot-scale additive manufacturing technologies, the work ensures industrial scalability and practical implementation potential.

Figure 2: Scale model of the footbridge

|

4. Consortium Partners Involved

Material development was carried out by Bio Base Europe Pilot Plant, LIST, and the University of Edinburgh, while the processing and manufacturing stages were handled by Aimen and coordinated by Acciona. Validation and characterization were supported by ISQ and University of Burgos, with additional contributions from Axia, RDC and Exelisis.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Ipsum, labore.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Quo ipsa optio ut ex porro quidem maiores dolorum esse temporibus, minus officiis ipsum delectus? Fugit ut laborum soluta laboriosam, tempore et.